The Evolution of Advanced Label Printing Technology in Modern Apparel Manufacturing

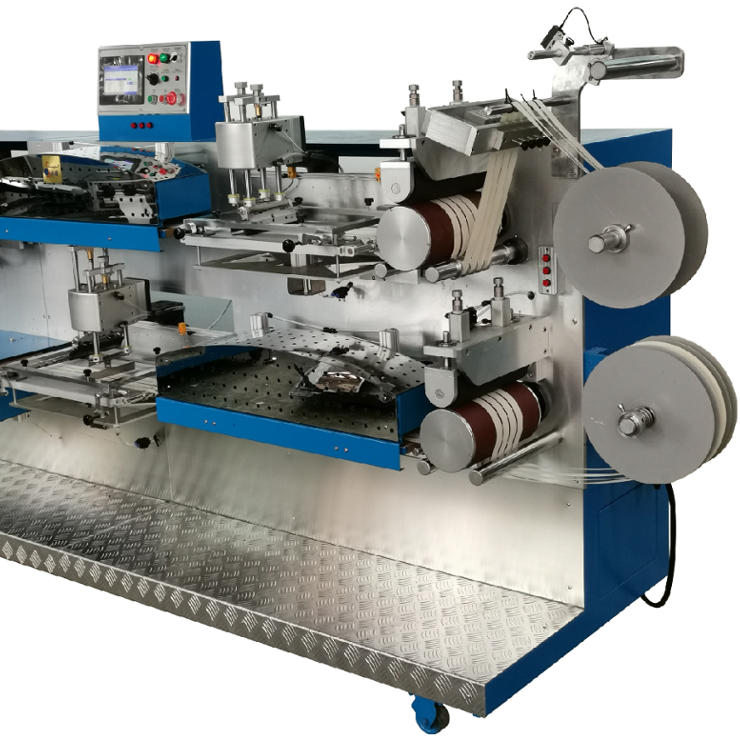

The landscape of apparel label printing has undergone a remarkable transformation in recent years. Modern printing machines have revolutionized how manufacturers approach complex design challenges, offering unprecedented precision and versatility in creating intricate label designs. These technological advances have not only enhanced the quality of apparel labels but have also streamlined production processes and expanded creative possibilities for brands worldwide.

Core Technologies Driving Modern Label Printing

Digital Printing Solutions

Digital printing technology represents a quantum leap in apparel label printing capabilities. These systems employ advanced printheads that can produce ultra-fine details and smooth color gradients with remarkable accuracy. The latest digital printers utilize specialized inks that bond effectively with various fabric materials, ensuring durability while maintaining design integrity even after multiple washes.

Modern digital printing machines feature sophisticated color management systems that can precisely match brand colors and reproduce complex patterns with consistency across production runs. This level of control allows manufacturers to maintain strict quality standards while meeting demanding production schedules.

Thermal Transfer Innovation

Thermal transfer printing has evolved to become a cornerstone of apparel label production. Contemporary machines utilize advanced thermal printheads that can achieve exceptional resolution, making it possible to reproduce intricate designs and small text with perfect clarity. The technology excels in creating durable labels that resist fading, scratching, and environmental factors.

These systems employ sophisticated temperature control mechanisms that ensure optimal ink transfer and adhesion to various label materials. The precision of modern thermal transfer printing allows for the creation of complex barcodes, QR codes, and other technical elements that are increasingly important in today's apparel industry.

Advanced Design Processing Capabilities

Automated Design Recognition

Modern apparel label printing machines incorporate powerful image processing algorithms that can analyze and optimize complex designs automatically. These systems can detect subtle variations in color, adjust for different material properties, and ensure optimal print quality without manual intervention. The sophisticated software can also predict potential printing issues and suggest corrections before production begins.

The integration of artificial intelligence has further enhanced these capabilities, allowing machines to learn from previous print jobs and continuously improve their performance. This adaptive technology ensures consistent quality across large production runs while reducing waste and setup time.

Variable Data Processing

Today's printing systems excel at handling variable data printing, enabling manufacturers to create unique identifiers and personalized elements within label designs. Advanced processing units can manage multiple data streams simultaneously, incorporating different text, graphics, and codes while maintaining perfect registration and print quality.

These capabilities are particularly valuable for brands that require serialized tracking information or need to produce labels with varying regional compliance information. The systems can seamlessly integrate this variable content without compromising the overall design aesthetic or production speed.

Material Handling and Quality Control

Intelligent Substrate Management

Modern printing machines feature sophisticated material handling systems that can work with a wide range of label substrates. These systems automatically adjust tension, temperature, and print settings based on the material properties, ensuring optimal results regardless of the substrate being used. Advanced sensors monitor material movement and make real-time adjustments to maintain precise registration.

The integration of automated material handling has significantly reduced setup times and material waste while improving overall production efficiency. These systems can handle delicate materials with the same precision as standard substrates, expanding the creative possibilities for designers.

Real-time Quality Monitoring

Quality control in modern apparel label printing has been revolutionized by the introduction of advanced monitoring systems. High-resolution cameras and sophisticated inspection algorithms continuously analyze print quality, detecting even minor imperfections in real-time. These systems can automatically adjust printing parameters to maintain quality standards throughout the production run.

The implementation of digital quality control has dramatically reduced defect rates and improved consistency across production batches. Manufacturers can now maintain detailed quality records and quickly identify and resolve any issues that arise during production.

Future Trends and Innovations

Sustainable Printing Solutions

The future of apparel label printing is increasingly focused on sustainability. New eco-friendly inks and materials are being developed that maintain high-quality results while reducing environmental impact. Advanced printing systems are being designed to minimize waste and energy consumption without compromising on design complexity or production speed.

Manufacturers are investing in technologies that enable the use of recycled materials and biodegradable inks, responding to growing consumer demand for sustainable fashion. These innovations are setting new standards for environmentally responsible label production.

Smart Label Integration

The integration of smart technology into apparel labels represents the next frontier in label printing. Modern machines are being equipped to handle the production of labels with embedded NFC chips, RFID tags, and other interactive elements. These advanced capabilities allow brands to create labels that serve both aesthetic and functional purposes.

The development of conductive inks and specialized printing techniques is opening new possibilities for creating intelligent labels that can interact with smartphones and other devices, enhancing the consumer experience and enabling better inventory management.

Frequently Asked Questions

What resolution can modern apparel label printers achieve?

Modern apparel label printing machines can achieve resolutions up to 1200 DPI (dots per inch), enabling extremely fine detail reproduction and sharp text even at small sizes. This high resolution ensures that complex designs, intricate patterns, and small text remain clear and legible.

How do printing machines maintain color consistency across different materials?

Advanced color management systems use spectrophotometric technology and sophisticated software algorithms to measure and adjust color output in real-time. These systems can compensate for different material properties and ensure consistent color reproduction across various substrate types.

What maintenance is required for optimal performance of modern label printing machines?

Modern printing machines require regular calibration, printhead cleaning, and software updates to maintain optimal performance. Most systems include automated maintenance routines and diagnostic tools that help operators identify and address potential issues before they affect production quality.

How do printing machines handle metallic or specialty inks?

Advanced printing systems utilize specialized printheads and temperature control systems designed specifically for metallic and specialty inks. These machines can precisely control ink laydown and curing processes to achieve optimal results with these challenging materials while maintaining consistent quality throughout the production run.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BN

BN

BS

BS

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ

KY

KY