Si të Mirëmbahet një Makinë Shtypi Flexo për Performancë të Gjatë Kohësh

Strategji Esenciale për Jetëgjatësinë e Pajisjeve të Shtypit Flexo

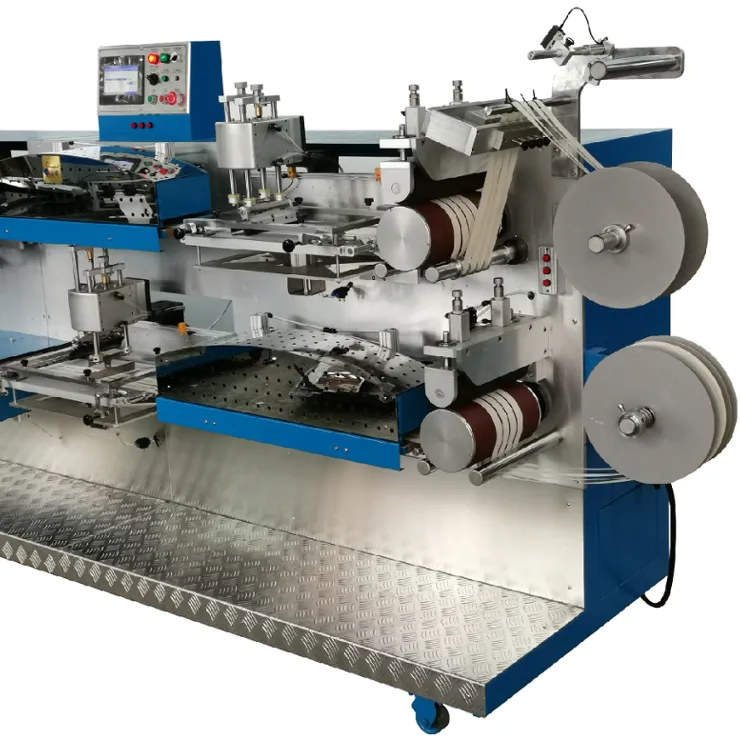

Kohëzgjatja dhe performanca e pajisjeve tuaja të shtypit fleksografik ndikojnë drejtpërdrejt në cilësinë e prodhimit dhe fitueshmërinë. Mirëmbajtja e duhur nuk ka të bëjë vetëm me zgjidhjen e problemeve kur paraqiten, por edhe me zbatimin e një rutine të plotë kujdesi që parandalon problemet para se të zhvillohen. masinë afërues prej fleksografisë kuptimi i mënyrës së mirëmbajtjes së këtyre pajisjeve të sofistikuara mund të jetë ndryshimi midis një daljeje konstante me cilësi të lartë dhe rregullave të shtrenjta të pushimit nga puna.

Njësitë prodhuese në tërë botën mbështeten në shtypjen fleksografike për paketimin, etiketat dhe aplikime të ndryshme industriale. Inxhinieria e precizionit pas këtyre makinave kërkon protokolle mirëmbajtjeje po aq të sakta për të siguruar performancën optimale vit pas viti. Në këtë udhëzues të hollësishëm, do të shpërndejmë aspektet themelore të mirëmbajtjes së makinës së shtypur fleksografike dhe do të ofrojmë strategji praktike për maksimizimin e jetëgjatësisë operative të pajisjeve tuaja.

Procedurat e Mirëmbajtjes Ditore

Protokolli i Inspektimit Para Fillimit të Punes

Përpara se të fillojë çdo serë shtypi, operatorët duhet të kryejnë inspektime vizuale të hollësishme të pjesëve të makinës së shtypur fleksografike. Kjo përfshin kontrollin e çdo shenje të konsumit në rrotat anilox, thikat e mjekut dhe cilindrat e pllakave. Inspektimi gjithashtu duhet të mbulojë tensionet e bronzave, gjendjen e rulive dhe pastërtinë e përgjithshme të stacionit të shtypur. Vendosja e një liste kontrolli sistematike para fillimit të punës siguron që asnjë zonë kritike të mos injorohet.

Një aspekt tjetër i rëndësishëm i kontrollit të përditshëm përfshin monitorimin e sistemeve të bojës dhe niveleve të lëngjeve. Viskoziteti i duhur i bojës dhe pastërtia kanë një ndikim të madh në cilësinë e shtypit. Operatorët duhet të kontrollojnë rezervuaret e bojës, pompën dhe sistemet e furnizimit për bllokimet ose ndotjen që mund të dëmtojnë performancën.

Kërkesat e Pastrimit Pas Prodhimit

Pastrimi i hollësishëm pas çdo serije prodhimi është themelor për ruajtjen e cilësisë së shtypit dhe zgjatjen e jetës së pajisjeve. Kjo përfshin heqjen e krejt mbetjeve të bojës nga rrotat anilox, thikat mjekuese dhe kamerat e bojës. Përdorimi i solucioneve të duhura pastrimi dhe ndjekja e procedurave të rekomanduara nga prodhuesi parandalon thatjen e bojës dhe shkaktimin e problemeve të ardhshme në shtyp.

Duhet t'i kushtohet veçanti vëmendje sistemeve të thatjes dhe njësive të ngurtësimit me UV, nëse ka. Këto pjesë duhet të jenë të lira nga prishjet e bojës së shtypit dhe ndonjë ndotës tjetër që mund të ndikojë në efikasitetin e ngurtësimit. Pastroja e rregullt e filtrares së ajrit dhe sistemeve të ventilimit siguron funksionim të rregullt dhe parandalon nxehtesin e tepërt.

Shkallë mbajtje përkufizuese

Detyrat e Mirëmbajtjes Javore

Rutinat e mirëmbajtjes javore fokusohen në kontrollime dhe rregullime më të hollësishme. Kjo përfshin kontrollimin dhe vajosjen e të gjitha pjesëve lëvizëse, verifikimin e tensionit të duhur në rripat e transmetimit dhe inspektimin e lidhjeve elektrike. Operatorët duhet gjithashtu të kryejnë një pastrim të thellë të zonave që janë më të vështirë për tu arritur dhe që mund të anashkalohen gjatë pastrimit ditnor.

Dokumentimi i aktiviteteve të mirëmbajtjes javore ndihmon në gjurmimin e modeleve dhe në identifikimin e problemeve potenciale para se të bëhen probleme serioze. Kjo përfshin regjistrimin e çdo zëri të pazakontë, vibracionesh ose variacionesh në performancë që mund të tregojnë probleme mekanike që po zhvillohen.

Vlerësimet Mujore të Sistemit

Mirëmbajtja mujore përfshin kontroll më të hollësishëm të sistemeve dhe kalibrime. Kjo përfshin testimin dhe rregullimin e sistemeve të regjistrimit, kontrollin e boshllëkut të dhëmbëzave dhe vlerësimin e gjendjes së rullesave dhe buksave. Duhet verifikuar aligjnimi i të gjitha stacioneve të printimit për të ruajtur cilësinë e printimit dhe për të parandaluar konsumin e papërbashkët.

Gjatë vlerësimeve mujore, duhet t'i kushtohet veçanti vëmendje sistemeve elektrike dhe elektronike. Panelet e kontrollit, sensorët dhe sistemet e sigurisë duhet të inspektohen dhe testohen në mënyrë të hollësishme për të garantuar funksionimin e besueshëm. Çdo azhurnim softueri ose kalibrime duhet gjithashtu të kryhen gjatë këtyre periudhave të planifikuara të mirëmbajtjes.

Kujdesi i Pjesëve Kritike

Mirëmbajtja e Rulles Anilox

Rrotat e anilox-it janë bërthama e procesit të shtypjes flekso, dhe gjendja e tyre ndikon drejtpërdrejt në cilësinë e shtypjes. Pasterimi i rregullt duke përdorur metoda të përshtatshme – siç është pastërimit me ultrazë ose solucione speciale pastruese – ndihmon në ruajtjen e një vëllimi konstant qelizash dhe parandalon shkrimin. Zbatimi i një skedi rotacioni për rrotat e anilox-it mund të ndihmojë në shpërndarjen e barabartë të fërkimit dhe zgjatjen e jetës së tyre operative.

Matja e rregullt e vëllimit të qelizave dhe gjendjes së sipërfaqes ndihmon në gjurmimin e modeleve të konsumimit dhe planifikimin e zëvendësimit përpara se cilësia e printimit të përkeqësohet. Rikondicionimi profesional i rulave anilox duhet të planifikohet bazuar në modelet e përdorimit dhe treguesit e konsumimit.

Optimizimi i Sistemit të Kufitinës së Doktorit

Sistemi i thjeshtës së mjekut kërkon konfigurim të saktë dhe mirëmbajtje të rregullt për të funksionuar në mënyrë efektive. Kjo përfshin rregullimin e këndit të duhur të thjeshtës, cilësimet e shtypjes dhe zëvendësimin e kohësh i thjeshtave të konsumuara. Përdorimi i thjeshtave të mjekut me cilësi të lartë dhe ruajtja e shtypjes së kontaktit të saktë ndihmon në parandalimin e konsumit të tepërt si në thjeshtë ashtu edhe në rrotën anilox.

Inspektimi i rregullt i mbajtësve të thjeshtave dhe i sigurive garanton mbajtjen e duhur të bojës dhe veprimin e qëndrueshëm të pastrimit. Çdo shenjë e konsumit të papërbashkët ose e dëmtimit duhet të nxisë menjëherë hetimin dhe korrigjimin për të parandaluar problemet e cilësisë.

Konsiderata të avancuara për mirëmbajtje

Sistemet e Monitorimit Diagnostik

Makineritë moderne të shtypjes flexo shpesh përfshijnë sisteme të sofistikuara monitorimi që mund të gjurmojnë metrikat e performancës dhe të parashikojnë nevojat për mirëmbajtje. Njohja dhe përdorimi i duhur i këtyre sistemeve ndihmon në optimizimin e planifikimit të mirëmbajtjes dhe parandalimin e pushimeve të papritura. Rishikimi i rregullt i të dhënave diagnostike mund të zbulojë tendencat që tregojnë probleme që po zhvillohen para se të ndikojnë në prodhim.

Zbatimi i teknologjive të mirëmbajtjes parashikuese, si analiza e vibracioneve dhe imazheria termike, mund të ofrojë paralajmërime të hershme për problemet mekanike të mundshme. Kjo qasje e drejtuar nga të dhënat për mirëmbajtjen ndihmon në optimizimin e alokimit të burimeve dhe minimizimin e interventions së panevojshme.

Masat e Kontrollit të Mjedisit

Mjedisi në të cilin funksionon një makinë printimi flekso ndikon në konsiderueshëm në performancën dhe nevojat e saj për mirëmbajtje. Ruajtja e niveleve të duhura të temperaturës dhe lagështisë ndihmon në parandalimin e problemeve me tharjen e bojës, manipulimin e materialit bazë dhe tensionin e pjesëve mekanike. Monitorimi i rregullt dhe rregullimi i kushteve mjedisore duhet të jetë pjesë e rutinës së mirëmbajtjes.

Masat për kontrollin e pluhurit dhe ndotjes, duke përfshirë filtrimin e duhur të ajrit dhe pastrimin e rregullt të sistemeve të menaxhimit të ajrit, ndihmojnë në mbrojtjen e pjesëve të ndjeshme dhe ruajtjen e cilësisë së printimit. Krijimi dhe ruajtja e një mjedisi të dhomës së pastër rreth pajisjeve të printimit mund të reduktojë në mënyrë të konsiderueshme kërkesat për mirëmbajtje.

Pyetje të Bëra Shpesh

Sa shpesh duhet të pastrohen thellë rrotat anilox?

Rrotat e Anilox duhet të pastrohen thellësisht të paktën njëherë në muaj, me pastrim më të shpeshtë kur bëhen operacione me vëllim të lartë ose kur përdoren bojëra të vështira. Frekuenca e saktë varet nga faktorë si vëllimi i prodhimit, llojet e bojërave të përdorura dhe kushtet mjedisore. Inspektimi i rregullt mikroskopik mund të ndihmojë në përcaktimin e intervaleve optimale të pastrimit.

Cilat janë shenjat që tregojnë se nevojitet mirëmbajtje menjëhershe?

Treguesit kryesorë përfshijnë cilësi të papërshtatshme shtypi, zhurma ose vibrime të pazakonta, kalim të parregullt të bojës, probleme regjistrimi ose variacione të papritura në shtypjen apo temperaturën operative. Çdo ndryshim i papritur në performancën e makinës duhet të hetohet menjëherë për të parandaluar problemet më serioze.

Si mund të ndikojë mirëmbajtja e rregullt në cilësinë e shtypit dhe produktivitetin?

Makinat e mirëmbajtura të shtypit flexo ofrojnë në mënyrë të qëndrueshme dalje me cilësi më të lartë me defekte dhe harxhime më pak. Mirëmbajtja e rregullt zvogëlon pushimet e paplanifikuara, zgjaton jetëgjatësinë e pajisjeve dhe optimizon efikasitetin e prodhimit. Kjo përkthehet në kontroll më të mirë të kostos dhe në kënaqësi më të lartë të klientit përmes cilësisë së qëndrueshme të shtypit.

Produkte të rekomanduara

Lajme të nxehta

-

Përsëriteni Larg Vlerat Kulturore të Preses Shtypshkronjave në Mbrojtjen dhe Shpalljen e Njohurive

2023-12-08

-

Roli i Preses Shtypshkronjave në Ekonomi Bektare

2023-12-08

-

Ndikimi Larg dhe Vlerat Ekologjike: Analiza e Larg dhe Vlerave Ekologjike të Industrisë së Shtypit

2023-12-08

-

Frontiera e Shtypjes: Shtypja 3D dhe Rinensimi Industri i Tij

2023-12-08

-

Evolutioni dhe Ndikimi i Presës së Shtypshme

2023-12-08

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BN

BN

BS

BS

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ

KY

KY